What is SepTor / Continuous Moving Bed?

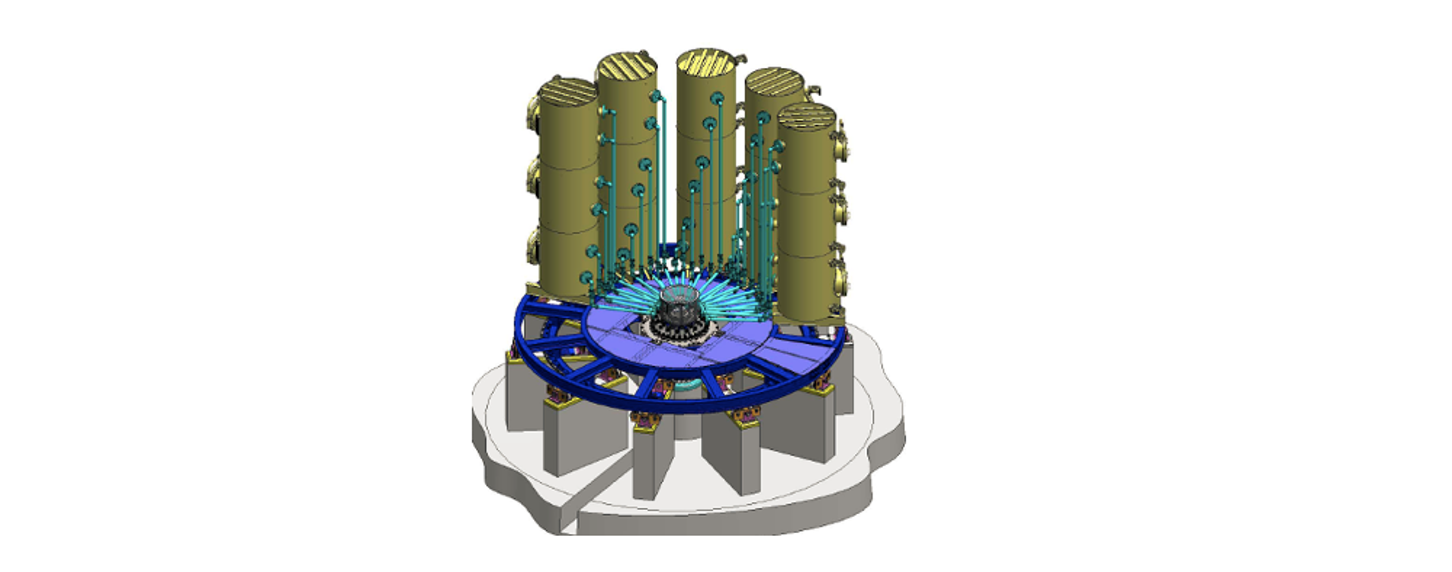

Continuous moving bed systems employ the principle of continuous operation to replace the traditional fixed bed systems which operate on the principle of batch operation. The system consists of resin columns and porous distribution rotary valves.

In continuous moving bed systems, the resin column series is divided into several functional areas. After the material enters the system, each resin column passes through these functional areas via the switching of rotary valves. This allows for the simultaneous execution of adsorption, water flushing, elution, regeneration, and other processes.

Suntar’s SepTor features advanced design concepts and superior production technology. It is easy to operate with a wide range of applications and can be customized to meet the separation requirements of various products.

The second-generation SepTor main unit was launched in 2002, featuring a single drive system and a more streamlined structure. Since the introduction of the second-generation product, multiple optimization and improvement iterations have been conducted.

With proven success across numerous industries, Suntar has developed and implemented dozens of SepTor systems, showcasing their reliability and adaptability for diverse applications.

Applications of Suntar's SepTor

- Conversion of sodium gulonate to gulonic acid

- Conversion of sodium Vitamin C to Vitamin C

- Purification of lysine

- Desalination of lactic acid

- Desalination of citric acid

- Direct Lithium extraction (DLE)

Key Benefits of Suntar's SepTor

- Stable product components and concentration.

- Optimise the consumption of resin and rinse water by 50-70%.

- Reduces chemical consumptions by 30-60%, lowering operating costs and wastewater discharge.

- Smaller footprint, easy installation and integration.

- Fully automated control system ensuring continuous stable production.