When strict regulations require low salinity discharge or minimal wastewater volume, companies must implement Zero Liquid Discharge (ZLD) systems to ensure compliance. Suntar’s advanced membrane technologies and multi-step treatment solutions maximise water recovery while minimising waste, delivering the highest efficiency and the lowest disposable waste volume in a ZLD process.

What is Zero Liquid Discharge (ZLD)?

Zero Liquid Discharge (ZLD) is a water treatment approach that recovers all water while removing contaminants as solid waste.

Pretreatment

Prepares wastewater for treatment and concentrates brine according to the specifications of downstream equipment. Pretreatment is essential for reducing Total Suspended Solids (TSS), Chemical Oxygen Demand (COD), and turbidity in wastewater. By effectively lowering these contaminants, pretreatment enhances the efficiency of subsequent wastewater treatment processes, ensuring smoother operation and improved overall treatment performance.

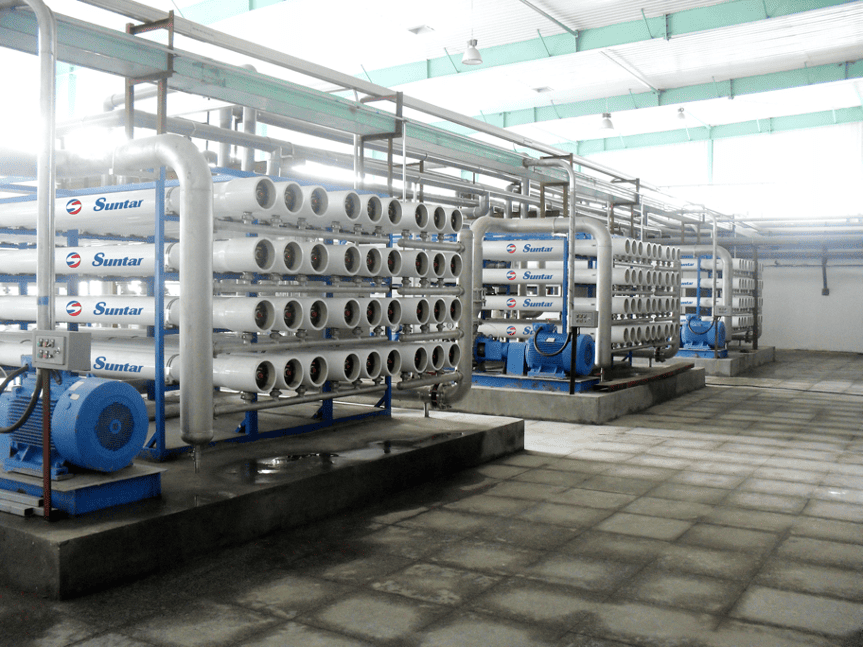

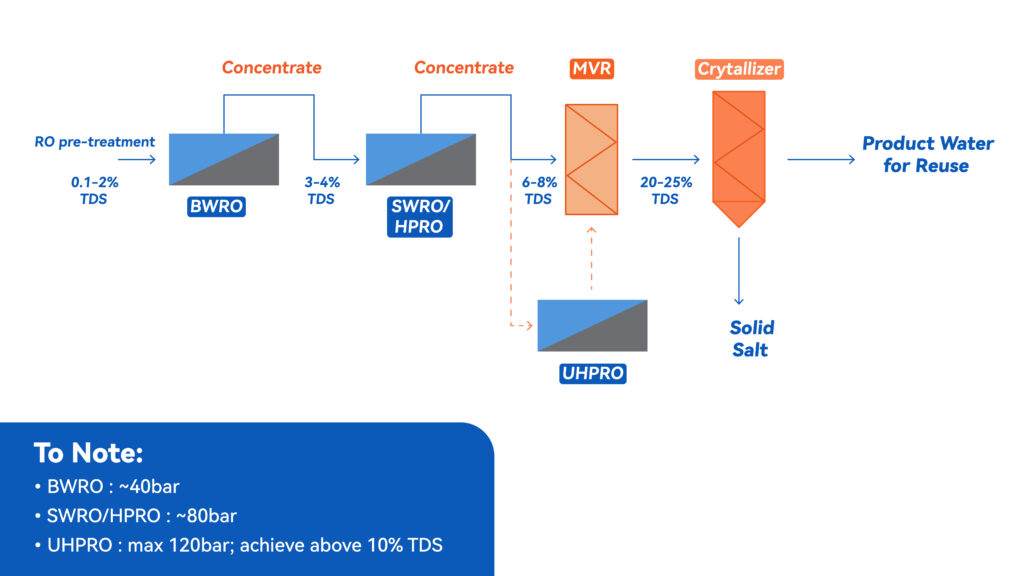

Membrane Treatment

In a Zero Liquid Discharge (ZLD) system, the concentration of dissolved solids is typically achieved using membrane technologies such as Reverse osmosis (RO), Electrodialysis (ED), or a combination of both. By integrating RO process, water recovery rates can achieve up to 95% or higher, maximizing efficiency and minimizing waste.

Evaporator

Brine concentration and volume reduction. After pretreatment, wastewater undergoes evaporation to remove water from the waste stream and concentrate the remaining contaminants. This process is typically carried out using a multi-effect evaporator or a thermal evaporator, ensuring efficient water separation and minimizing waste disposal.

Crystallizer

Produce solids for disposal or reuse. The concentrated waste stream must undergo crystallization to remove additional water, resulting in a solid waste product that can be further processed or disposed of safely.

Relevant Technologies

Suntar’s membrane technologies are applied in both pretreatment and membrane treatment processes. Our Spiral Wound RO Membrane, designed to operate at ultrahigh pressures of up to 120 bar, significantly reduces the volume of water entering brine concentrators, evaporation ponds, and crystallizers, resulting in lower operating costs and improved energy efficiency.

Additionally, our Spiral Wound NF Membrane, tailored for demanding industrial applications, delivers exceptional salt separation performance for NaCl and Na₂SO₄, ensuring optimal process efficiency and reliability.

Industrial Applications

- Power generation

- Textile dyeing

- Petrochemicals and refineries

- Biopharmaceuticals

- Food and beverage processing

Key Benefits

- Water Recovery: The process aims to recover as much water as possible for reuse within the facility.

- Solid Waste Management: The remaining impurities are concentrated and converted into solid waste, which is often disposed of in landfills or used in other industrial applications.

- Environmental Protection: By eliminating wastewater discharge, ZLD prevents pollution of natural water bodies.