Turning wastewater into high-quality effluent, MBR technology delivers sustainable solutions for cleaner water management.

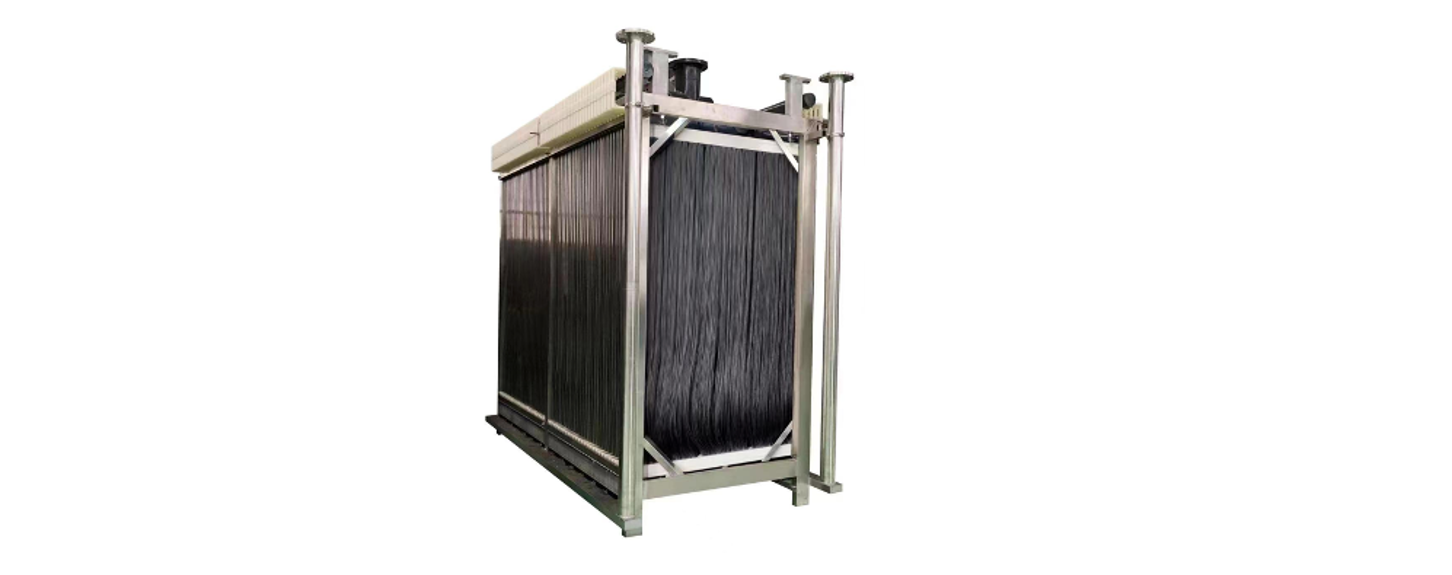

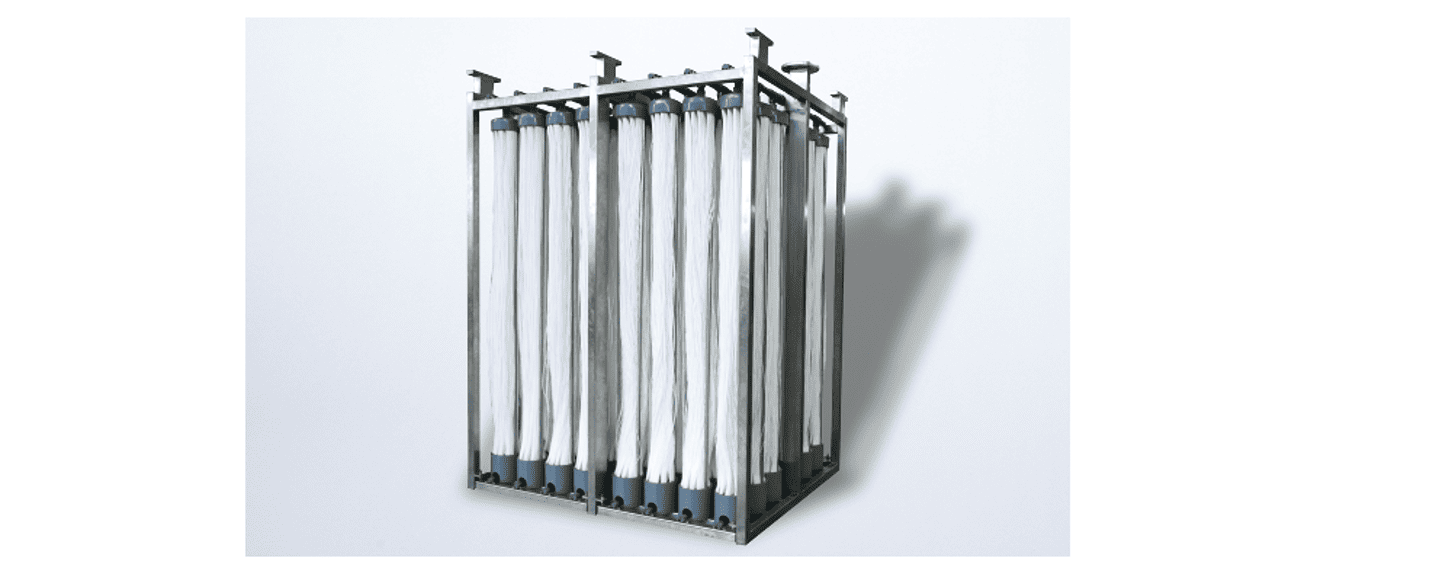

A Membrane Bioreactor (MBR) is a wastewater treatment process that integrates a biological treatment unit such as activated sludge with a membrane filtration unit (typically microfiltration or ultrafiltration) to separate solids from liquids. This technology allows for efficient wastewater treatment while producing high-quality effluent. In the MBR process, membranes serve as a solid-liquid separation device, retaining the biomass within the bioreactor before discharging the treated effluent into the environment.

Applications of MBR

MBR applies to various industries such as municipal wastewater treatment for treating domestic and municipal sewage, industrial wastewater treatment for sectors like food and beverage, biopharmaceutical, textile, and chemical industries., water reuse in non-potable applications.

Technical Features of MBR

- Effective retention of suspended solids.

- Maintains relatively high MLSS.

- Maintaining low sludge production while shortening HRT as compared to conventional biological systems.

- Retains soluble macromolecular substances, which are eventually degraded.

- Promotes the growth of nitrifying bacteria, improving the denitrification rate.

Key Benefits of MBR

- 1.5- 2x Higher Water Flux: Handles tough wastewater with ease.

- 1.5x Greater Anti-Fouling: Maximises uptime and reduces cleaning frequency.

- Durability: Graphene-PVDF for longer membrane lifespan and lower OPEX.

- Compact Footprint: Ideal for decentralised, on-site treatment.