World's first mass production using CCPS technology for high mechanical strengths and anti-fouling performance.

Hollow Fiber Membranes are precision filters that act as selective barriers, removing particles based on size. The membrane surfaces contain fine pores that determine which particles can pass through, based on a molecular weight cut-off value. Typically, water and small dissolved particles pass through the filter, while larger solid particles are retained and rejected.

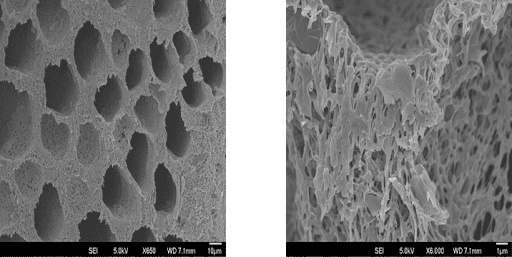

Graphene Hollow Fiber Membrane features an in-house patented graphene-modified PVDF structure with internal support, providing outstanding flux and anti-fouling properties. It represents the world’s first mass-produced industrial graphene membrane, enhanced by CCPS technology.

Applications of Graphene Hollow Fiber Membrane

A key application of hollow fiber membranes is in water treatment and purification. These membranes are essential for removing contaminants, pathogens, and particulates, ensuring that water is safe for consumption and use across various industries. Their role in desalination, particularly in converting seawater into potable water, highlights their importance in addressing global water scarcity challenges.

Graphene Hollow Fiber Membranes are available in two forms: pressurised UF and submerged UF.

Tecnical Features of Graphene Hollow Fiber Membrane

Utilises Suntar’s Patented Materials

Made with Graphene-enhanced PVDF (Polyvinylidene fluoride) formula.

External Pressure (Out-In)

Reduces channel blockage and extends membrane lifespan.

Meets international standards for fiber breakage resistance.

Made with Graphene-enhanced PVDF (Polyvinylidene fluoride) formula.

Flexible Active Area

Offers 50–68 m² of active membrane area per module.

Key Benefits of Graphene Hollow Fiber Membrane

Exceptional Filtration Performance

Due to the distributed graphene forms that support its structure. The pores within the membrane reduce water resistance, resulting in a water flux that is 1.5-2.0 times higher than that of ordinary membranes.

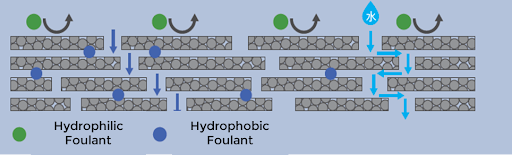

Strong Anti-Fouling Properties

Hydrophobic groups formed on the graphene surface contributed to superior anti-fouling performance. This inherent hydrophobicity effectively repels hydrophilic pollutants during filtration, leading to a performance that is over 1.5 times greater than that of standard membranes.