What is Leachate Treatment

Leachate treatment is a critical process in managing liquid waste generated from landfills, which often contains high concentrations of suspended solids, dissolved solids, organic and inorganic compounds, heavy metals and other pollutants. This liquid, called leachate, is generated when rainwater percolates through waste, dissolving organic and inorganic substances, including harmful chemicals, heavy metals, and biological contaminants. Effective treatment is essential to prevent environmental contamination, public health risks and comply with discharge regulations.

Leachate Source

Landfill

Garbage Transfer Station

What does Leachate contain?

Organic Matter :

Includes biodegradable and non-biodegradable compounds.

Inorganic ions :

Such as ammonia, chloride, sulfate, and heavy metals (e.g., cadmium, lead, mercury).

Pathogens:

Microorganisms that pose health risks.

Toxic Chemicals:

Includes polycyclic aromatic hydrocarbons (PAHs), pesticides, and solvents.

Hazardous Chemicals:

Highly acidic or alkaline chemicals

Recalcitrant Compounds:

Difficult to treat as they are not easily biodegradable

Process Flow for Leachate Treatment

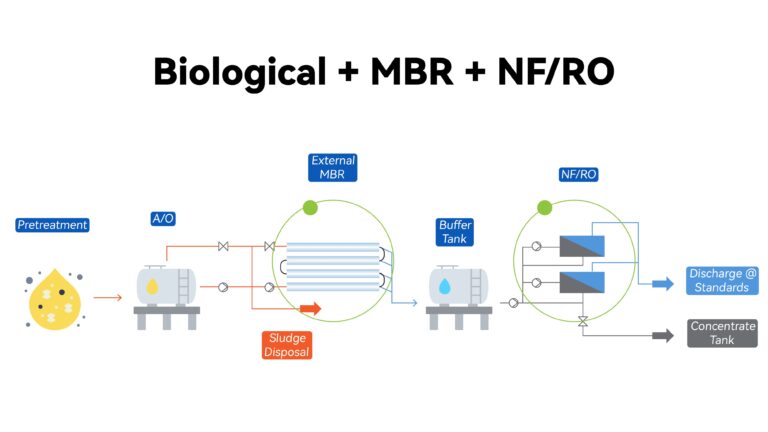

Biological + MBR + NF/RO

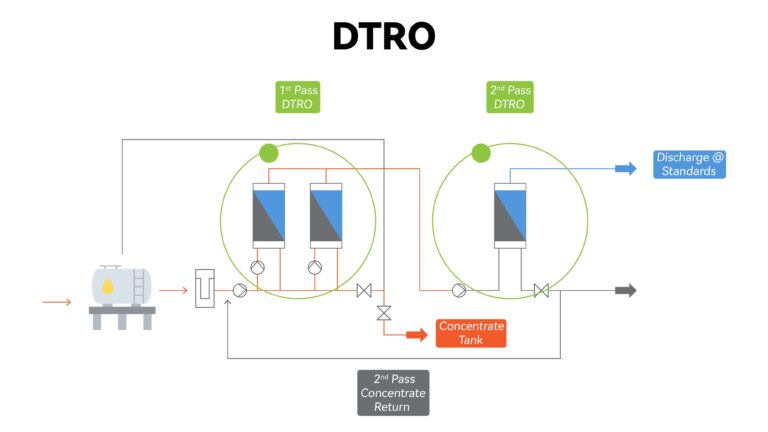

DTRO

Relevant Technologies

Membrane technology is essential in leachate treatment, offering advanced purification capabilities to produce high quality treated water.

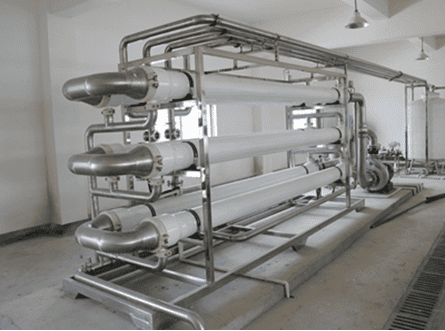

Spiral Wound Membrane Technology

Spiral Wound Membrane Technology encompasses nanofiltration, and reverse osmosis levels to treat leachate that have underwent pre-treatment. It features small flow channels that are prone to clogging and challenging to clean, making high-quality feedwater essential. The membrane core is designed with a simple structure, ensuring low energy consumption during operation. Additionally, it offers a high packing density (<1000 m²/m³) along with excellent filtration performance and high membrane precision.

Tubular Membrane Technology

Suntar’s tubular membrane offers high fouling resistance and excellent operating flux. Both the membrane element and housing are replaceable. It is widely used in the MBR process for leachate treatment, as well as in pre-treatment applications for oilfield and gasfield fracturing flowback water, circulating cooling water discharge, coal chemical wastewater, and more.

DTRO Membrane Technology

Suntar’s DTRO membrane technolgy is designed for resistance to fouling, high pressure, high COD, and high TDS levels. It requires only simple pre-treatment and is suitable for applications with a high Silt Density Index (SDI) of up to 15, demonstrating excellent resistance to fouling and scaling. The membrane module is easy to maintain, allowing for the replacement and reuse of individual components. It is also simple to clean, with performance parameters that can be effectively restored. The system operates under ultra-high pressure, achieving high water recovery rates while delivering stable product water quality across a wide range of applications.

Membrane Bioreactors (MBRs)

Membrane bioreactors (MBRs) are highly effective for leachate treatment due to their ability to combine biological degradation with membrane filtration, significantly enhancing treatment performance compared to conventional systems.