In the food and beverage industry, separation involves isolating different types of products to prevent contamination and ensure safety standards are met. These processes are also used to remove impurities, recover solids, and concentrate specific ingredients, enhancing the quality and efficiency of production.

Dairy Products

In the dairy industry, process separation plays a critical role in dividing milk and its derivatives into distinct components for various applications. This not only enhances product quality but also increases operational efficiency.

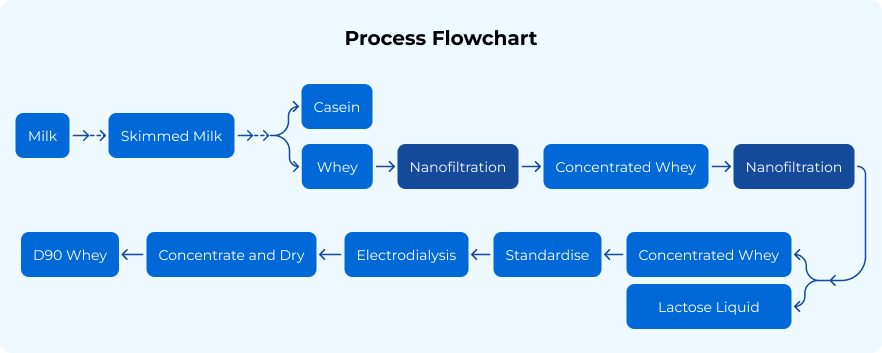

Process Flowchart

Relevant Technologies

Membrane technology has transformed this process by offering energy-efficient, environmentally friendly, and high-quality separation solutions.

Reducing Wastewater and Environmental Pollution

Membrane technology allows for the efficient separation and recovery of valuable components such as proteins and lactose from whey and other dairy byproducts. This minimises waste generation and supports compliance with stringent environmental regulations, significantly lowering the industry’s environmental impact.

Simplifying Production and Reducing Energy Use

Membrane-based separation methods, such as ultrafiltration and reverse osmosis, can replace more complex and energy-intensive techniques like evaporation. These processes concentrate milk or whey without the need for high heat, resulting in streamlined production and notable energy savings.

Preserving Product Purity – No Additives Needed

Unlike traditional chemical-based processes, membrane technology uses physical separation, eliminating the need for additives. This ensures the purity of dairy products – an increasingly important factor for health-conscious consumers seeking clean-label options.

Milk Standardization

Adjusting the fat and protein content of milk to meet specific product requirements.

Ceramic Microfiltration (MF) Membranes: Ceramic Microfiltration (MF) technology can selectively separate fat globules from proteins.

Concentration of Milk and Whey:

Ceramic Ultrafiltration (UF) Membranes: Concentrates milk by removing water and small molecules (lactose, salts) while retaining proteins.

Spiral Wound Reverse Osmosis (RO) Membranes: Removes water from milk or whey for concentration before drying processes.

Protein Fractionation

Spiral Wound Ultrafiltration (UF) Membranes: Separating casein and whey proteins for specialized products like infant formula or sports nutrition.

Lactose Reduction and Recovery

Spiral Wound Ultrafiltration (UF) and Spiral Wound Nanoflo®️ Membranes are used to remove lactose for producing low-lactose or lactose-free products.

Spiral Wound Nanoflo® Membrane can recover lactose from whey streams for further processing.

Bacterial and Spore Removal

Ceramic Microfiltration (MF) Membrane: Removes bacteria and spores to improve shelf life and product safety, especially in products like cheese and milk powder.

Desalting

Spiral Wound Nanoflo® Membrane reduces salt content in whey to produce high-purity protein concentrates.

Low-Temperature Operation to Prevent Thermal Degradation

Spiral Wound Reverse Osmosis (RO) technology are used for desalination and water purification. They remove dissolved salts, minerals, and contaminants from feedwater, providing high-purity water essential for steam generation and cooling systems in power plants. RO is critical for achieving the required water quality in both thermal and nuclear power plants.

Tea Extraction

Tea extraction involves the use of various methods to separate desirable compounds, such as polyphenols, caffeine, and essential oils, from tea leaves. Traditional methods like hot water extraction can be energy-intensive and may lead to the loss of delicate compounds. Membrane technology, particularly through processes like microfiltration, ultrafiltration, and reverse osmosis, offers an efficient alternative.

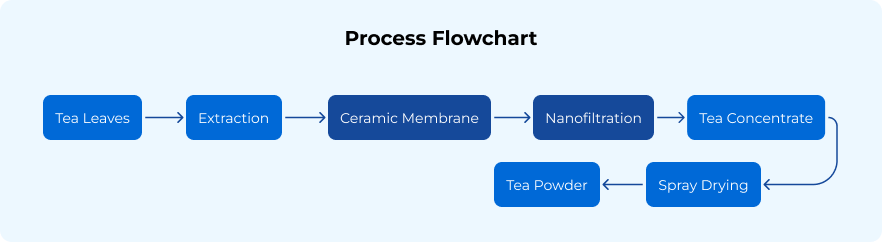

Process Flowchart

Relevant Technologies

Our expertise is in developing membrane processes that enable selective separation, enhancing the purity and concentration of tea extracts while reducing energy consumption and preserving flavor and nutrients. Membrane technology also provides better control over the extraction process, leading to improved overall product quality, with sanitary design to meet the requirements of healthy food production.

Clarification and Filtration

Ceramic Ultrafiltration (UF) technology is used to remove suspended solids, tannins, and larger particles while retaining smaller molecules like polyphenols and amino acids.

Concentration

Spiral Wound Nanoflo®️ technology is used for the concentration of tea extraction by efficiently separating and concentrating on soluble components while rejecting unwanted impurities and water.

Spiral Wound Reverse Osmosis (RO) technology concentrates tea extracts by removing water while retaining the flavor and aroma compounds. This is a cost-effective alternative to evaporation methods and avoids thermal degradation of sensitive components.

Decaffeination

Spiral Wound Nanoflo®️ technology can selectively reduce caffeine content in tea extracts while retaining other desirable bioactive compounds.

Glucose

Our expertise lies in developing a series of membrane separation systems integrated with moving bed technology for sugar production, which has earned high recognition from sugar manufacturers.

In the glucose production process, membrane technology is applied in the separation, concentration, and purification stages. This technology provides a more sustainable and efficient alternative to traditional methods.

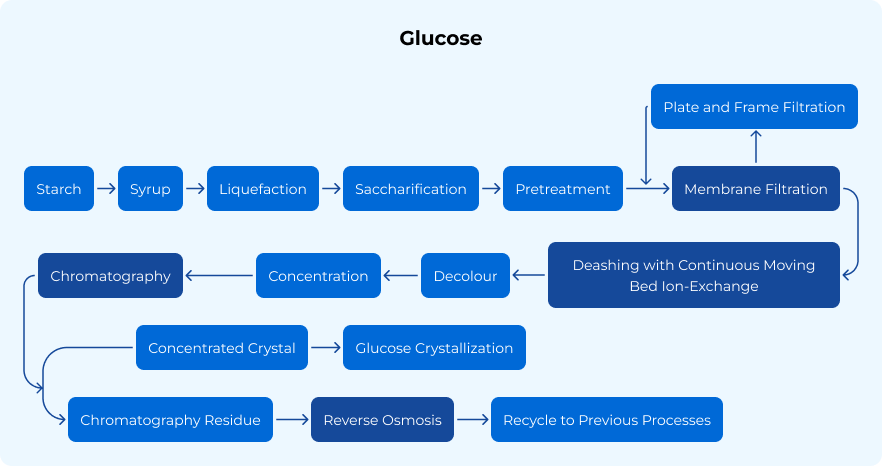

Process Flowchart

Relevant Technologies

SepTor®️

SepTor®️ technology enhances product quality while reducing production costs. These fully automated systems operate continuously, ensuring stable and efficient high production.

Spiral Wound Ultrafiltration (UF) Membranes

Our Spiral Wound Ultrafiltration (UF) technology effectively removes impurities from the saccharification liquid, resulting in a high quality filtrate that minimizes subsequent resin contamination and prevents color reversion in the saccharification liquid.

Spiral Wound Nanoflo®️ Membranes

Our Spiral Wound Nanoflo®️ technology purifies saccharification liquid in a single step, achieving high glucose purity efficiently. Additionally, it enables precise product grading by separating, ensuring consistent and high-quality glucose for various applications.

What is Sugar Alcohol?

The sugar alcohol industry has experienced significant growth due to the increasing demand for low-calorie, sugar-free, and diabetic-friendly alternatives to traditional sugar. Sugar alcohols, such as sorbitol, xylitol, and erythritol, are widely used in food, beverage, and pharmaceutical products.

Membrane technology is essential in sugar alcohol production, particularly in purification and concentration processes. Utilizing techniques like Ultrafiltration (UF) and Nanofiltration (NF), it effectively removes impurities, eliminates unwanted byproducts, and concentrates sugar alcohol solutions with high efficiency. This allows producers to achieve high-purity products while minimizing energy consumption and enhancing process sustainability.

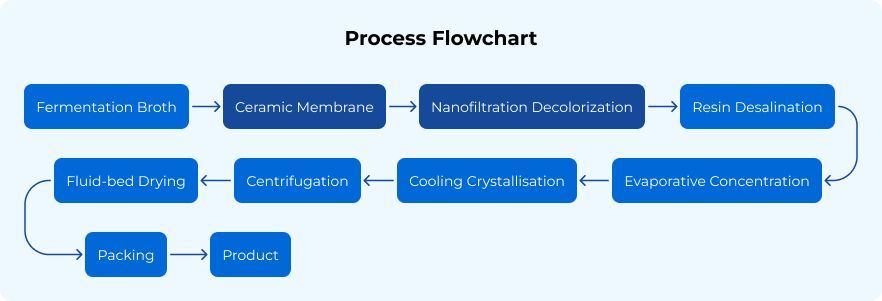

Process Flowchart

Relevant Technologies

We specialize in membrane technology and continuous moving bed systems for producing xylitol, erythritol, sorbitol, and other products, while also advancing a biological fermentation method for xylitol extraction.

Ceramic Membranes

Ceramic membranes clarify fermentation broth, achieving higher filtrate quality while reducing resin contamination and bacterial recovery in subsequent processes.

Spiral Wound Ultrafiltration (UF) Membranes

Spiral Wound Ultrafiltration (UF) technology is used to remove proteins and pigments, enhancing product quality.

Spiral Wound Nanoflo®️ Membranes

Spiral Wound Nanoflo®️ Technology concentrates sugar alcohol, enhancing crystal recovery.

CR chromatographic separation

Chromatography enhances resin efficiency and product recovery.

Organic Acid

Organic Acid production often requires precise separation processes to achieve high purity and efficiency, particularly in pharmaceutical and food industries. Membrane technology plays a crucial role in these separations due to its ability to selectively remove impurities, concentrate solutions, and recover valuable amino acids.

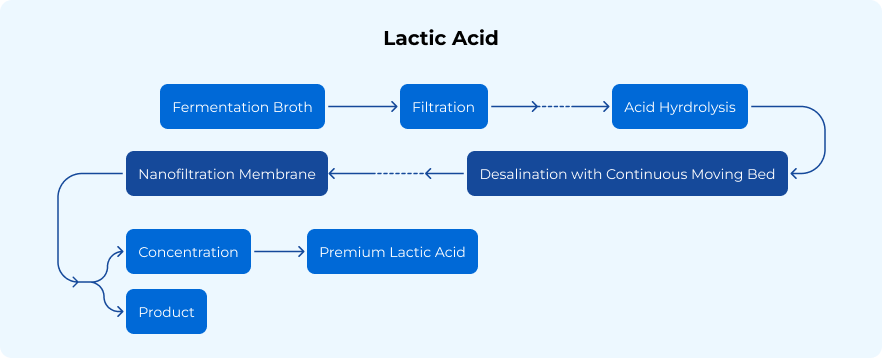

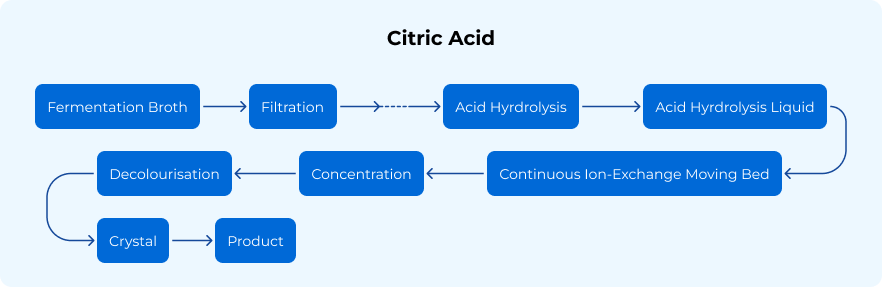

Process Flowchart

Relevant Technologies

Our expertise lies in technologies such as Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO), which are widely utilized in amino acid processing. These membrane-based solutions provide energy-efficient alternatives to traditional methods like crystallization and solvent extraction, reducing chemical usage and waste while enhancing process sustainability for cost-effective and environmentally friendly amino acid production.

Ceramic Microfiltration (MF) Membranes

Ceramic Microfiltration (MF) membrane clarifies fermentation broth, improves filtrate quality and reduces resin pollution in the subsequent processes.

Spiral Wound Nanoflo®️ Membranes

Spiral Wound Nanoflo®️ technology reduces sugar concentration in the product, enhancing its thermal stability and resulting in high-quality lactic acid.

SepTor®️

SepTor®️ enhances desalination stability, improves product recovery rates, reduces resin consumption for citric acid and lactic acid and increases product concentration.

Chromatography

Chromatography has transformed the extraction of organic acids by offering a precise, efficient, and scalable method for separation and purification. By using specialized chromatographic media and optimized elution processes, industries can achieve high-purity organic acids with minimal loss and contamination.

Wine

Wine is a beverage produced through the fermentation of fresh grapes and grape juice. Process separation is essential in the wine industry to ensure product quality, stability, and clarity. Key processes such as filtration, clarification, and stabilization effectively remove suspended solids, yeasts, and bacteria while preserving flavor and aroma. Membrane technology plays a crucial role in achieving these goals efficiently and sustainably. Microfiltration and ultrafiltration are used for wine clarification and microorganism removal, while reverse osmosis is applied for alcohol content adjustment and flavor enhancement. These membrane processes enable precise separation, reduce energy consumption compared to traditional methods, and help maintain the wine’s integrity.

Relevant Technologies

Our expertise in membrane technologies provides effective solutions for various stages of wine production, including clarification, purification, concentration, and stabilization, ensuring optimal quality and efficiency.

Clarification of Wine

Ceramic Microfiltration (MF) and Ultrafiltration (UF) technologies play a vital role in wine clarification, enhancing both quality and stability. These filtration methods effectively remove suspended solids, yeast, and fine particles that could cause turbidity or spoilage. During the process, wine passes through a membrane filter, which selectively retains larger particles and microorganisms while allowing smaller components to pass through. This results in a clearer wine without altering its flavor or aroma. Key benefits include improved clarity, enhanced visual appeal, extended shelf life, and a lower risk of microbial spoilage, ensuring the wine remains fresh and of premium quality.

Purification and Concentration of Sugar

Spiral Wound Nanoflo®️ and Spiral Wound Reverse Osmosis (RO) technologies enhance the purification and concentration of sugars in grape juice and wine. These advanced membrane filtration methods efficiently remove water while purifying sugars, allowing for precise control of sugar levels during fermentation or adjusting sweetness to achieve the desired wine characteristics.

Spiral Wound Nanoflo®️ and Spiral Wound Reverse Osmosis (RO) technologies selectively remove water and low-molecular-weight molecules, such as salts, effectively concentrating the sugars in grape juice or wine. This process enhances flavor intensity, allows precise sugar content adjustment, and ensures consistency in wine profiles. Reverse Osmosis, in particular, is ideal for concentrating grape juice before fermentation, helping to achieve the desired balance of sweetness and flavor in the final wine.

Adjustment of Alcohol Content

The adjustment of alcohol content in wine is effectively achieved using Spiral Wound Reverse Osmosis (RO) technology. This method involves applying pressure to the wine, causing the membranes to separate alcohol and water from the larger components, such as sugars, acids, and phenolic compounds, which are retained.

By selectively removing alcohol and water, winemakers can reduce the alcohol content in wines that are too strong, ensuring the final product meets legal or desired alcohol limits.

The process preserves the wine’s flavor and aroma, allowing winemakers to maintain the integrity and balance of the wine while achieving the preferred alcohol concentration. This technique is particularly valuable in regions with strict alcohol regulations or for producing wines with more approachable alcohol levels.

Stabilization of Wine

The stabilization of wine is a critical step in ensuring its quality and longevity, achieved through the use of Ceramic Microfiltration (MF) and Ultrafiltration (UF) technologies. These methods are designed to eliminate bacteria, yeast, and other microorganisms that could cause spoilage or unwanted microbial activity.

During the process, the wine is passed through membranes with pore sizes specifically designed to retain microorganisms while allowing the wine’s essential components to pass through. This filtration ensures microbiological stability before bottling.

The benefits include an extended shelf life, enhanced stability during storage and distribution, and a significant reduction in spoilage risks, such as unwanted fermentation after bottling. This process helps maintain the wine’s quality and consistency for consumers.

Purification of Feed Water for Production

The purification of feed water for wine production is a vital step in maintaining the quality and safety of the winemaking process. Ceramic Ultrafiltration (UF) and Spiral Wound Reverse Osmosis (RO) technologies are employed to purify the water used for cleaning and diluting concentrates, ensuring it meets the necessary standards.

During the process, Ceramic Ultrafiltration (UF) technology remove microorganisms and suspended solids, while Spiral Wound Reverse Osmosis (RO) technologies eliminate salts and other dissolved contaminants. This dual filtration system produces high-quality water that prevents contamination and supports consistent product quality. By using purified water, wineries can enhance the overall integrity of the production process and ensure the wine meets both safety and taste expectations.

Recovery of Wine from Pomace

The recovery of wine from pomace is an innovative application of membrane separation technologies, such as Ceramic Microfiltration (MF) and Ultrafiltration (UF) technologies that helps minimize waste and maximize yield. After fermentation, the pomace, which consists of grape skins, seeds, and stems, often retains a significant amount of residual wine or juice.

Through membrane separation, the pomace is subjected to pressure, allowing the liquid to pass through membranes while retaining the solid components. This process effectively extracts the remaining wine or juice from the pomace. The benefits include increased overall wine yield, reduced production waste, and improved cost-efficiency, making it a sustainable and economically beneficial practice in winemaking.

Plant Extraction

Plant extraction involves isolating valuable bioactive compounds, such as antioxidants, alkaloids, and essential oils, for applications in food, pharmaceuticals, and cosmetics. Membrane technology plays a vital role in this process by enabling efficient separation, purification, and concentration under mild conditions that preserve compound integrity. Through selective filtration, membranes reduce solvent usage, lower energy consumption, and ensure high-purity extracts. This sustainable approach enhances recovery efficiency, minimizes waste, and maintains the quality of sensitive bioactive molecules.

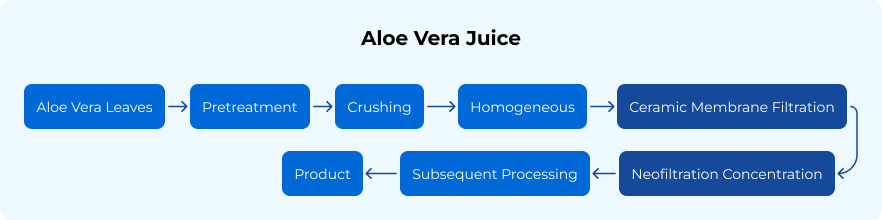

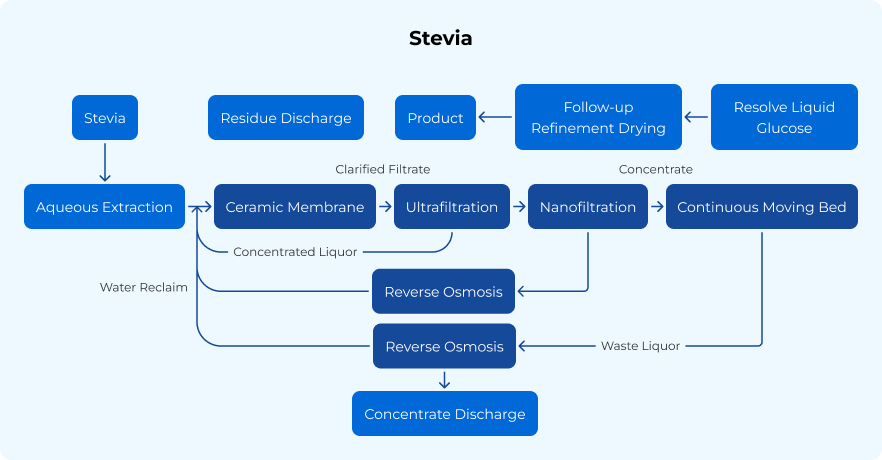

Process Flowchart

Relevant Technologies

Our expertise in membrane technology allows for the extraction of clarified liquids with superior filtrate quality, minimizing resin pollution and reducing solvent consumption in downstream processes.

Ceramic Microfiltration (MF) Membranes

Ceramic Microfiltration (MF) technology is used to extract clarified liquid from plant material, ensuring higher filtrate quality by effectively removing impurities such as solids and resins. This process reduces contamination, minimizes solvent consumption in downstream processes, and enhances the efficiency, sustainability, and cost-effectiveness of plant extraction.

Spiral Wound Ultrafiltration (UF) Membranes

Spiral Wound Ultrafiltration (UF) technology removes large molecules, such as proteins, pigments, and other macromolecules, from the plant extract. This step improves the quality of the extract by removing unwanted substances and enhancing the purity of the final product.

Spiral Wound Nanoflo®️ Membranes

Spiral Wound Nanoflo®️ technology is used to concentrate plant extracts, enhancing the recovery of active ingredients such as essential oils, antioxidants, and bioactive compounds. This process improves extraction efficiency and yield while reducing evaporative losses, making it more energy-efficient and sustainable.

SepTor®️

SepTor®️ reduces resin consumption and improves efficiency in the extraction process by allowing for better control over ion exchange and separation of target compounds.

Fermentation

Fermentation is a biological process in which microorganisms such as bacteria, yeast, or fungi convert substrates, typically sugars or other organic compounds into valuable products like alcohols, organic acids, antibiotics, enzymes, or biofuels. In industrial fermentation, once the reaction takes place in a bioreactor or fermenter, the resulting mixture is a complex broth. This broth contains the target product (such as ethanol, lactic acid, or antibiotics), microbial cells (such as yeast, bacteria, or fungi), residual substrates (unconsumed sugars or nutrients), various by-products and impurities, as well as water and other components. Effective downstream processing is essential to separate and purify the desired product from this complex mixture.

Relevant Technologies

Our expertise in membrane technology allows for the extraction of clarified liquids with superior filtrate quality, minimizing resin pollution and reducing solvent consumption in downstream processes.

Ceramic Microfiltration (MF) Membranes

Ceramic Microfiltration (MF) technology is primarily used in the initial stages of fermentation broth processing for cell separation and clarification. It effectively removes suspended solids, cell debris, and bacteria from the fermentation mixture without damaging the target products. Ceramic MF membranes, in particular, offer high chemical and thermal stability, making them ideal for harsh fermentation environments and for ensuring consistent, high-throughput separation of biomass from the liquid phase.

Spiral Wound Ultrafiltration (UF) Membranes

Spiral Wound Ultrafiltration (UF) technology is applied to concentrate and purify valuable macromolecules such as proteins, enzymes, and polysaccharides in the fermentation broth. With pore sizes smaller than MF, UF effectively retains high molecular weight compounds while allowing water and smaller solutes to pass through. This makes UF an essential step for increasing product concentration and purity while maintaining biological activity, especially in the biopharmaceutical and enzyme production industries.

Spiral Wound Nanofiltration (NF) Membranes

Spiral Wound Nanofiltration (NF) technology provide selective separation by retaining larger organic molecules and multivalent ions while allowing smaller solutes like monovalent salts, sugars, and solvents to pass. In fermentation processes, NF is commonly used for partial desalination, sugar removal, and product concentration, making it valuable in applications such as organic acid purification.

Spiral Wound Reverse Osmosis (RO) Membranes

Spiral Wound Reverse Osmosis (RO) technology plays a key role in the final concentration and purification stages by removing water and virtually all dissolved solutes, including small organic compounds and salts. In the fermentation industry, RO is widely used to concentrate fermentation products such as ethanol, lactic acid, or citric acid, reducing downstream evaporation costs. Its high rejection capabilities ensure that valuable end-products are efficiently recovered with minimal contamination.