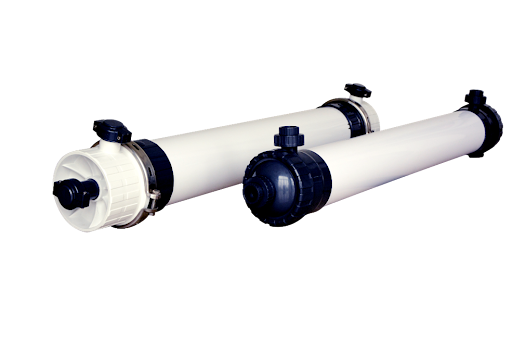

Upgrade to Pressurised UF for a compact design and consistently superior filtration performance.

Pressurised Ultrafiltration (UF) is a membrane filtration process that uses pressure to remove large molecules, suspended solids, and other impurities from water and various solutions. A liquid is forced through a semipermeable membrane under pressure, with the membrane’s pore size determining which materials can pass through. Smaller particles pass through, while larger particles are retained by the membrane.

Applications of Pressurised UF

- Pressurised UF can be used in various industries such as wastewater treatment, water purification, RO/NF pre-treatment.

Technical Features of Pressurized UF

High Flux, High Porosity

With super-hydrophilic formula technology, the membrane fiber surface exhibits unique hydrophilic properties, offering high porosity and excellent water permeability.

High Strength

An inner support reinforcement structure enhances the mechanical strength of the membrane fibers, reducing the risk of breakage.

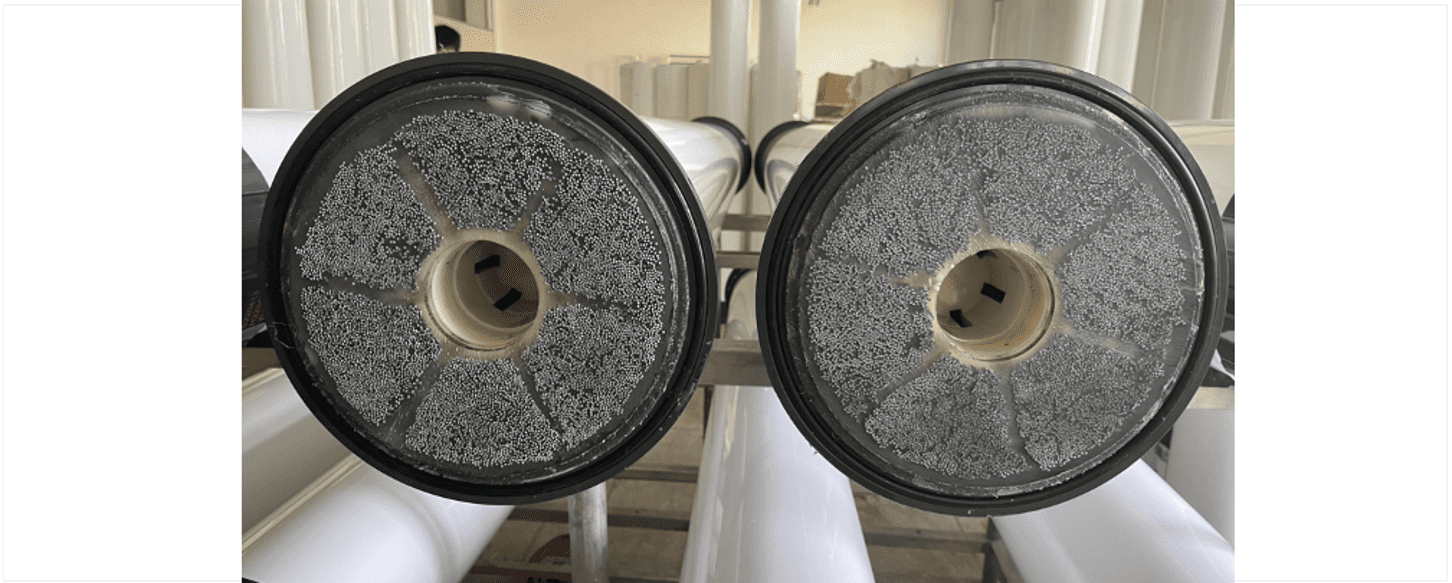

Strong Anti-fouling Properties

Utilises an outside-in flow configuration, enabling high solids capacity, easy cleaning, low filtration resistance, minimal transmembrane pressure difference, and reduced energy consumption per unit.

Key Benefits of Pressurised UF

- Small Footprint: The compact module design enables multiple pressurized modules to be arranged together, maximizing membrane surface area within a limited footprint.

- Ease of Operation: easy to install, operate, and expand.

- Stable Permeate Water Quality: Uniform pore size distribution, filtration precision is high and turbidity of permeate is ≤0.5 NTU.

- Strong Anti-fouling Capabilities: Outside-in flow configuration - high tolerance for feed solids, easy to clean.

- Reduced costs: lower both energy and treated water costs.

- Integrity Testing: Pressure systems can efficiently detect even small breaches in membrane integrity.