Smart Solutions for an Optimised Footprint

The MemBox system is an innovative solution designed to reduce freshwater consumption by treating and reusing harvested water for irrigation, toilet flushing, and other non-potable applications.

Key Features

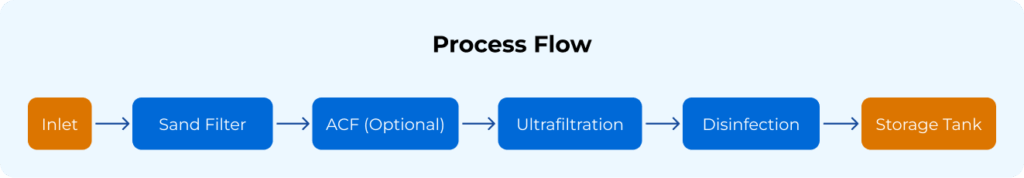

Efficient Filtration

Includes a sand filter system that can automatically backwash, ensuring consistent performance. The ultrafiltration (UF) system achieves high water recovery rates and achieves tap water standard.

Versatility

Depending on the source water quality, the treated water can be made potable.

Disinfection

Equipped with a dosing system for effective water disinfection, ensuring safety for non-potable uses.

Environmentally Friendly

Utilizes a UV system for disinfection without generating secondary pollution.

Process Flowchart

Product Portfolio

Deployed System

Sand Filter + Ultrafiltration Module

Tank + Disinfection System

Smart Solutions for an Optimised Footprint

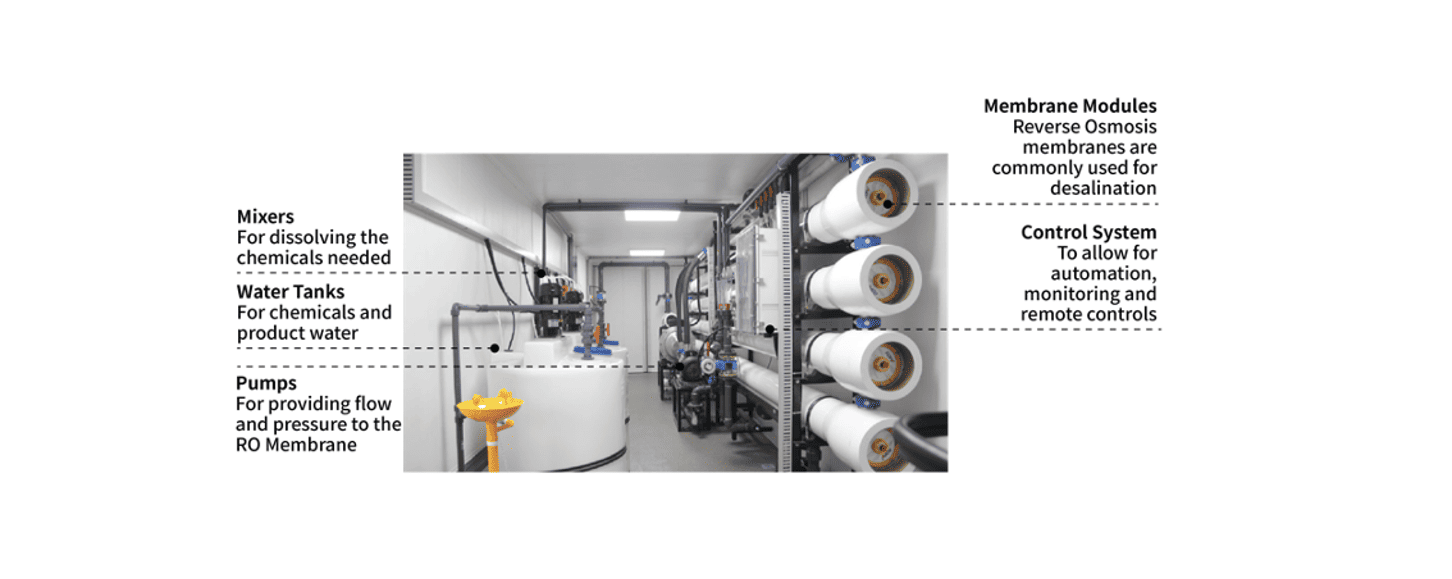

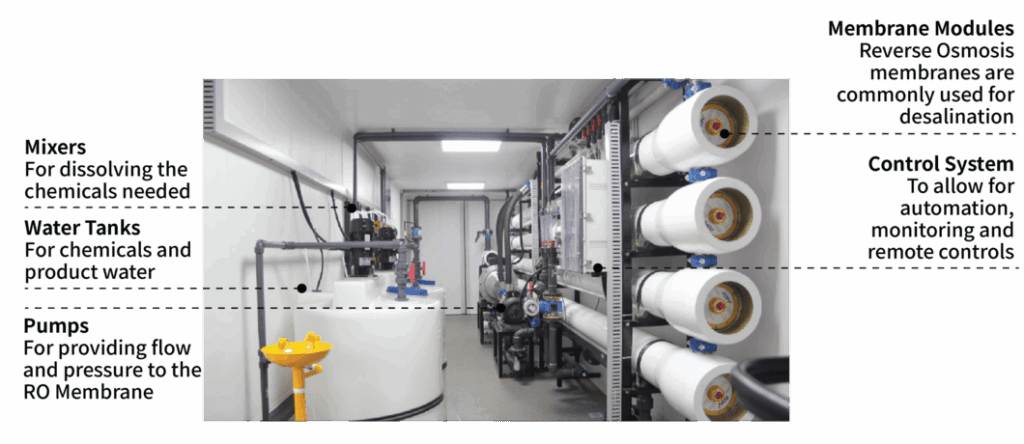

Desalbox is a modular, compact desalination system designed to convert seawater or brackish water into clean, potable water, using membrane-based technologies like reverse osmosis (RO) or ultrafiltration (UF).

Key Features:

Efficient Design

Containerized systems enable rapid installation and commissioning, minimizing setup time and costs.

Unique Application

Suitable for off-site usage, where fresh water demand is scattered. Including Military Water supply, island residents, construction sites, oil drilling platforms.

Flexible Capacities

Can utilize 1 to 2 containers to produce freshwater ranging from 50 m³ to 2000 m³ per day, meeting diverse water demand requirements.

Cost Efficient

Optimized for affordability without compromising on performance or reliability.

Advanced Automation

Automatic switching of equipment, emergency operation, fault alarm, remote control, Communication with mobile phones, real-time monitoring of equipment operation.

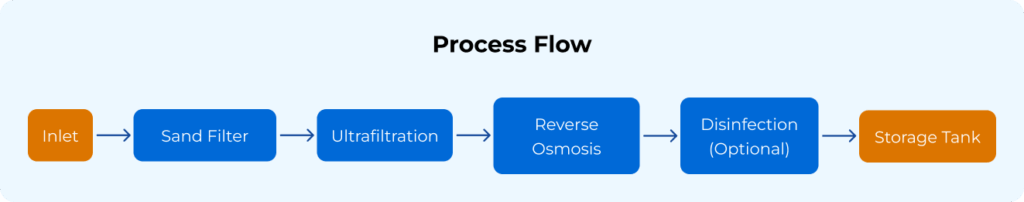

Process Flowchart

Product Portfolio

Desalbox

Smart Solutions for an Optimised Footprint

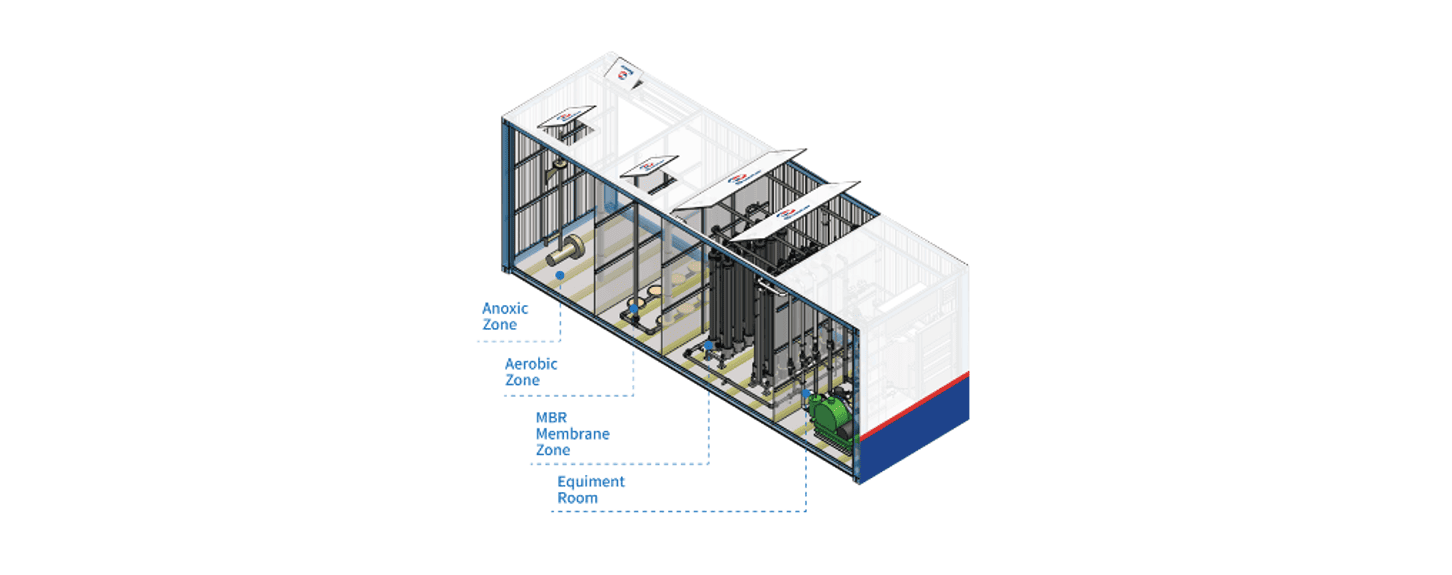

Suntar’s MBR Box is a compact, modular wastewater treatment system that combines biological treatment with advanced membrane bioreactor (MBR) technology. It’s designed to deliver high-quality effluent in a small footprint, making it ideal for decentralised or small-scale wastewater treatment applications such as: residential and commercial areas, industrial wastewater, remote sites or temporary installations.

Key Features

Consistent Effluent Quality

Produces high-quality, stable effluent that meets environmental discharge regulations.

High Shock Load Resistance

Operates with MLSS concentrations 2–3 times higher than mainstream processes, ensuring reliable performance under variable conditions.

Advanced Automation

Features automated equipment switching, emergency operation capabilities, fault alarms, and remote control with real-time monitoring of equipment operation.

Smaller footprint

Water treatment capacity per ton versus space is reduced up to 50%.

Efficient

The assembly and commissioning of integrated equipment are completed on-site within 15 to 30 days.

Minimised Sludge Discharge

Designed for efficient sludge management, significantly reducing sludge output and associated handling costs.

Product Portfolio

Anoxic/Aerobic Membrane Bioreactor (AO MBR)

Biological treatment with membrane filtration. It removes organic matter, nitrogen, phosphorus. BOD and COD will be reduced by micro-organisms.

Membrane filtration consists of ultrafiltration or microfiltration membranes that separate the treated wastewater from the activated sludge.