In the biopharmaceutical industry, membrane technologies are essential for producing high-purity products like vitamin C, vitamin B12, antibiotics, collagen, and enzymes. These technologies are valued for their ability to ensure product safety, efficacy, and adherence to strict regulatory standards.

Suntar provides comprehensive solutions and services specifically tailored to the process separation needs of the biopharmaceutical sector. Our custom-designed systems address the unique challenges of this specialized market. With deep expertise in processes and applications, Suntar is your trusted partner for innovative and reliable pharmaceutical solutions.

What is Vitamins Separation?

Vitamins are often referred to as ‘eternal’ products due to their essential role in sustaining life. These organic substances are crucial for maintaining the biological activities of animals and serve as vital active compounds for overall health and well-being.

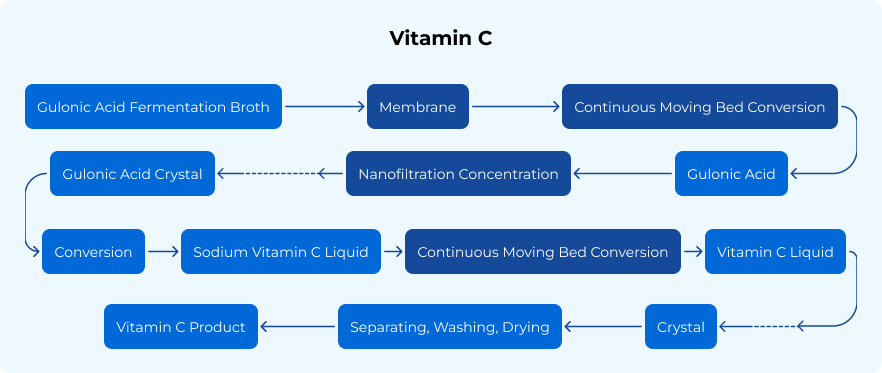

Suntar’s specialized membrane separation technology and continuous moving bed technology play a key role in the vitamin separation process. These innovative approaches enhance efficiency, ensure high purity, and support sustainable production in the vitamin industry.

Process Flowchart

Relevant Technologies

Suntar’s advanced membrane technologies provide innovative solutions for improving vitamin production processes,offering significant benefits over traditional methods:

Flow-cel membranes

Flow-cel technology replaces conventional filtration methods like plate and frame systems to clarify fermentation broth, enhancing filtrate quality and reducing resin contamination in downstream processes.

Spiral Wound Ultrafiltration (UF) membranes

Spiral Wound Ultrafiltration (UF) technology effectively removes proteins, decolorizes solutions, and improves overall product quality.

Spiral Wound Nanoflo® membranes

Spiral Wound Nanoflo® technology can concentrate vitamins and antibiotics, reducing evaporation loss and associated costs.

SepTor®

SepTor® replaces fixed-bed ion exchange, reducing resin, water and chemical consumption.

CR chromatographic separation

Chromatography separates and recovers vitamin solution

What are Antibiotics?

Antibiotics are a class of secondary metabolites with anti-pathogenic or other bioactive properties, produced by bacteria, molds, or other microorganisms during their lifecycle.

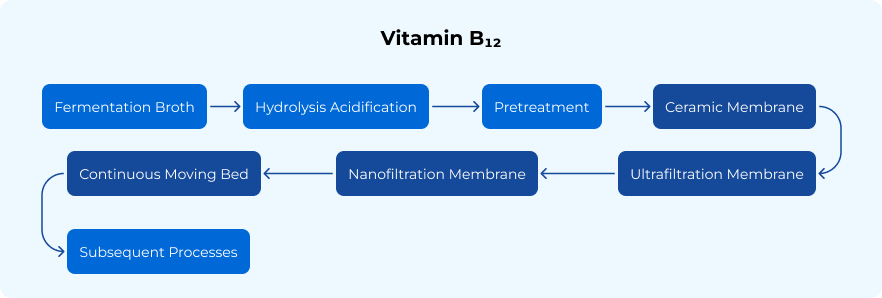

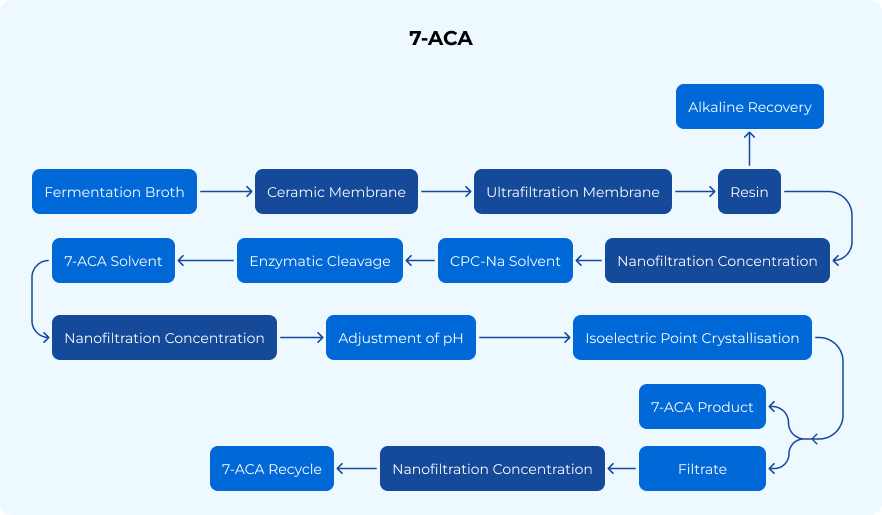

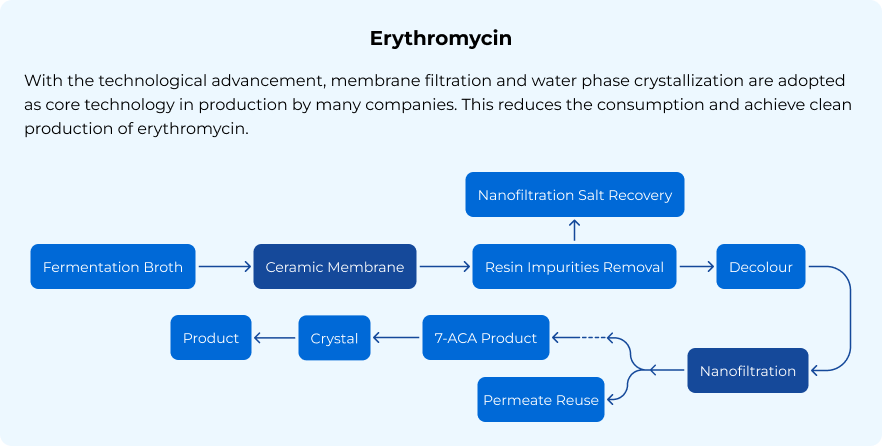

Suntar’s membranes are extensively utilized in the antibiotic industry, leveraging advanced membrane separation technology and continuous moving bed technology.

Process Flowchart

Relevant Technologies

Ceramic membranes and Flow-Cel Membranes

These membrane technologies replaces traditional filtration methods such as plate and frame systems. This improves the clarity of the fermentation broth, enhances the quality of the filtrate, and reduces resin contamination and solvent consumption in subsequent processes.

Spiral Wound Ultrafiltration (UF) Membranes

Spiral Wound Ultrafiltration (UF) technology removes proteins, decolorizes, and improves overall product quality.

Spiral Wound Nanoflo® Membranes

Spiral Wound Nanoflo® Technology concentrates antibiotics, with increased crystallization yields and minimizes evaporation losses.

SepTor®

SepTor® replaces fixed-bed ion exchange, reducing resin, water and chemical consumption.

What is Amino Acid?

Amino acids, essential organic compounds containing amino and carboxyl groups, are vital for numerous biological functions, with over 300 natural varieties and 22 critical to human health. Amino acid separation is a crucial process where high-purity amino acids are essential. Traditional methods like crystallization and chromatography are effective but can be resource-intensive.

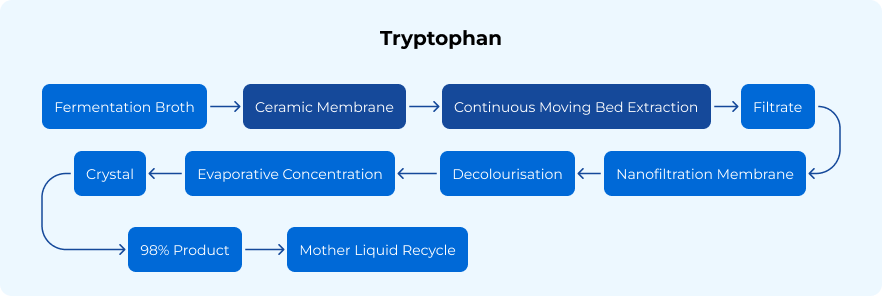

Membrane technology offers a more efficient alternative, providing selective separation based on molecular size, charge, or affinity. Technology like nanofiltration (NF), ultrafiltration (UF), and reverse osmosis (RO) are widely employed to concentrate, purify, and fractionate amino acids. Membranes enable energy-efficient, scalable, and environmentally friendly processes, reducing chemical usage and waste while ensuring high separation performance, making them indispensable in modern amino acid production.

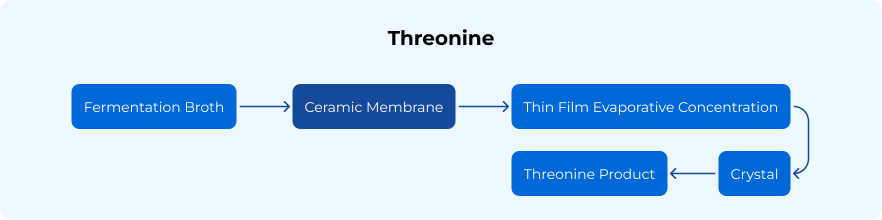

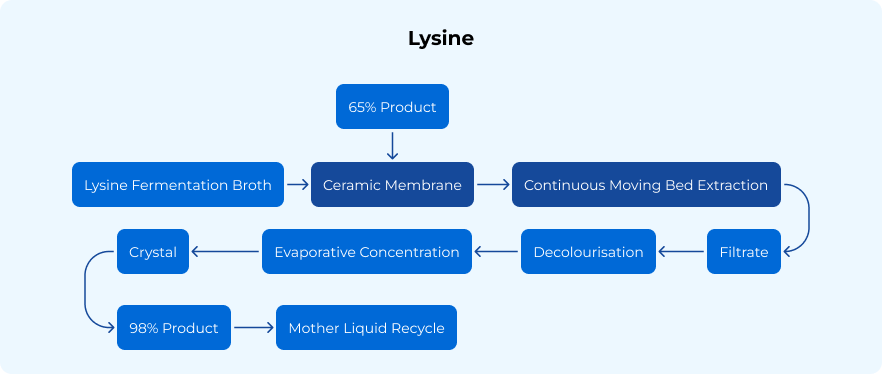

Process Flowchart

Relevant Technologies

Our expertise encompasses various amino acid production processes, including lysine, tryptophan, threonine, arginine, glutamine, leucine, valine, isoleucine, homoserine, methionine, and citrulline. Suntar ensures efficient and high-purity amino acid production, meeting the stringent standards of the food, pharmaceutical, and biotech industries.

Ceramic Microfiltration (MF) Membranes

Ceramic Microfiltration (MF) Technology is primarily used for pretreatment, removing bacteria, suspended solids, and microorganisms before further processing.

Spiral Wound Ultrafiltration (UF) Membranes

Spiral Wound Ultrafiltration (UF) Technology separates proteins, enzymes, and other macromolecules from amino acid solutions. The product is widely used for concentration and clarification.

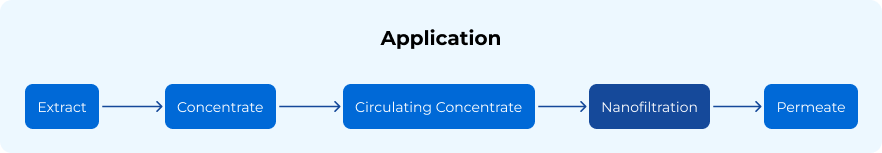

Spiral Wound Nanoflo® Membranes

Spiral Wound Nanoflo® Technology is useful for demineralization, concentration, and selective separation of amino acids based on molecular weight and charge properties. The product is able to remove salts and other impurities while retaining amino acids.

Spiral Wound Reverse Osmosis (RO) Membranes

Spiral Wound Reverse Osmosis (RO) Technology provides high-level concentration and purification by removing water and low-molecular-weight impurities, increasing the amino acid concentration.

SepTor®

SepTor® replaces fixed-bed ion exchange, reducing resin, water and chemical consumption.

What is Traditional Chinese Medicine?

The production of liquid medicine typically takes 1 to 2 months due to repeated processing, which increases the risk of bacterial contamination and reduces the concentration of active ingredients. As a result, most products exhibit high impurity levels, poor clarity, and limited stability, hindering the industrialization and commercialization of traditional Chinese medicine. Membrane separation technology addresses these challenges, improving the efficiency and quality of production.

Process Flowchart

Relevant Technologies

Spiral Wound Ultrafiltration (UF) Membranes

Spiral Wound Ultrafiltration (UF) technologies replace traditional filtration methods such as plate and frame systems. This improves the clarity of the fermentation broth, enhances the quality of the filtrate, and reduces resin contamination and solvent consumption in subsequent processes.

Spiral Wound Nanoflo® Membranes

Spiral Wound Nanoflo® technology efficiently retain macromolecules such as proteins and polysaccharides while allowing smaller bioactive compounds to pass through. This process enhances the purity and concentration of beneficial compounds, ensuring the therapeutic potency of the medicine. Our Spiral Wound Nanoflo® technology helps to remove unwanted salts and contaminants, improving the overall quality and safety of TCM extracts.