Engineered for excellence in durability and reliability, our ceramic membranes provide outstanding filtration performance, even in the most demanding applications.

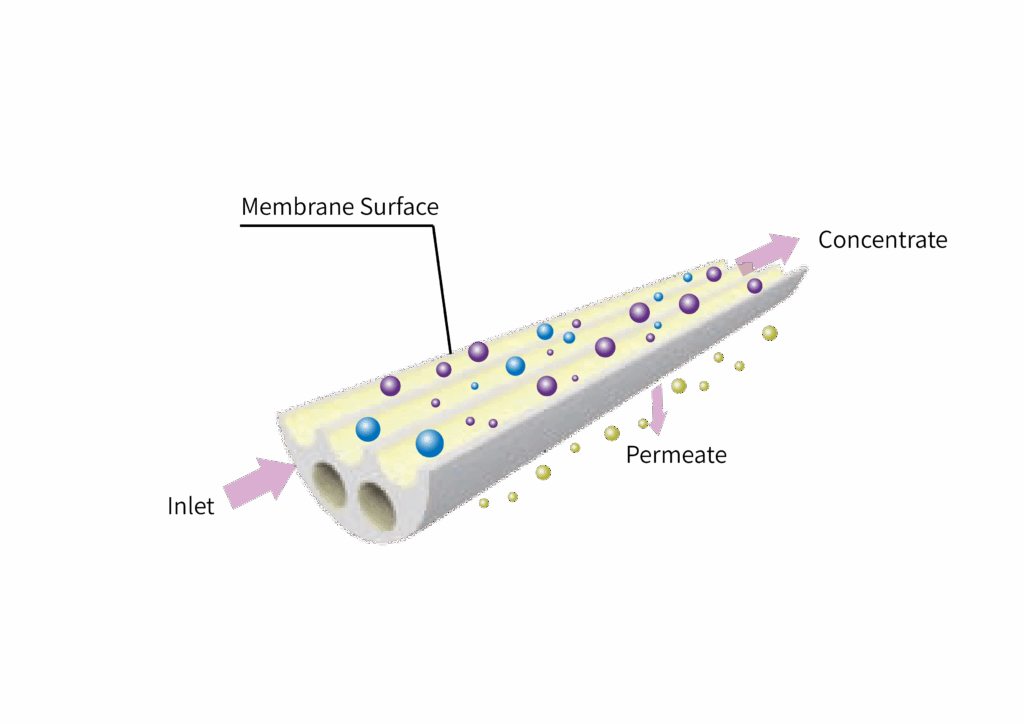

Suntar’s Ceramic Membrane features a tubular design, offering a structural advantage over conventional flat-sheet ceramic membranes on the market. These membranes are developed using unique nanodispersion technology, which ensures uniform granule distribution, enhances hydrophilicity, and provides higher permeate flux with lower filtration resistance.

They are available in a wide range of pore sizes, making them suitable for applications in microfiltration and ultrafiltration. Pore sizes can be selected based on factors such as the viscosity and suspended solids content of the liquid being treated, ensuring effective separation.

Our membranes typically range from 25 mm to 40 mm in diameter and are 1200 mm in length—common dimensions in the industry. Designed for both performance and versatility, this advanced ceramic membrane optimizes purification, resource recovery, and the treatment of oily wastewater and ultrafine particle-laden effluents, making it ideal for solid-liquid separation and pre-treatment processes.

Suntar’s ceramic membrane system can operate continuously and can be fully automated, featuring precise cleaning and backwash capabilities.

Applications of Ceramic Membrane

- Ceramic membranes are used for various process separation applications, including amino acids, antibiotics, vitamins, and sugar alcohols.

- They are also used in water treatment applications such as oil-water separation, resource recovery, hardness removal, and sewage/water treatment.

Technical Features of Ceramic Membrane

- High-purity aluminum oxide (Al₂O₃) is sintered at high temperatures, providing the membrane with excellent mechanical strength and superior corrosion resistance.

- The unique nanodispersion technology evenly distributes the granules in the monogranular film layer, ensuring reliable filtration performance and long-lasting anti-fouling properties.

Key Benefits of Ceramic Membrane

High Pressure and Temperature Resistance

Suitable for pressures ranging from 0.1 to 1 Mpa and temperatures up to 300°C.

Acid and Alkali Resistance

Ideal for use in harsh pH environments.

Wear Resistance

Easier for cleaning and backwashing.

Strong anti-microbial degradation

Versatility

Well-suited for solid-liquid separation and pretreatment processes.