Membrane Filtration

Spiral Wound Membrane

Suntar provides spiral wound membrane equipment/systems with a variety of filtration accuracy for different requirements, including spiral wound membrane systems in the range of microfiltration (MF), Ultra-filtration (UF), Nanofiltration (NF), and Reverse Osmosis (RO).

Typical spiral wound NF membrane equipment/systems are suitable for desalination, reduction of monosaccharides, and concentration processes.

Reverse Osmosis (RO) water treatment technology is well-known and widely used for pure or ultra-pure water production in all kinds of applications that requires pure or ultra-pure water.

Features

Principal Advantages

Extremely high packing density, optimized cost

Low operating pressure, and low requirements on maintenance

Full automatic control

Typical Applications

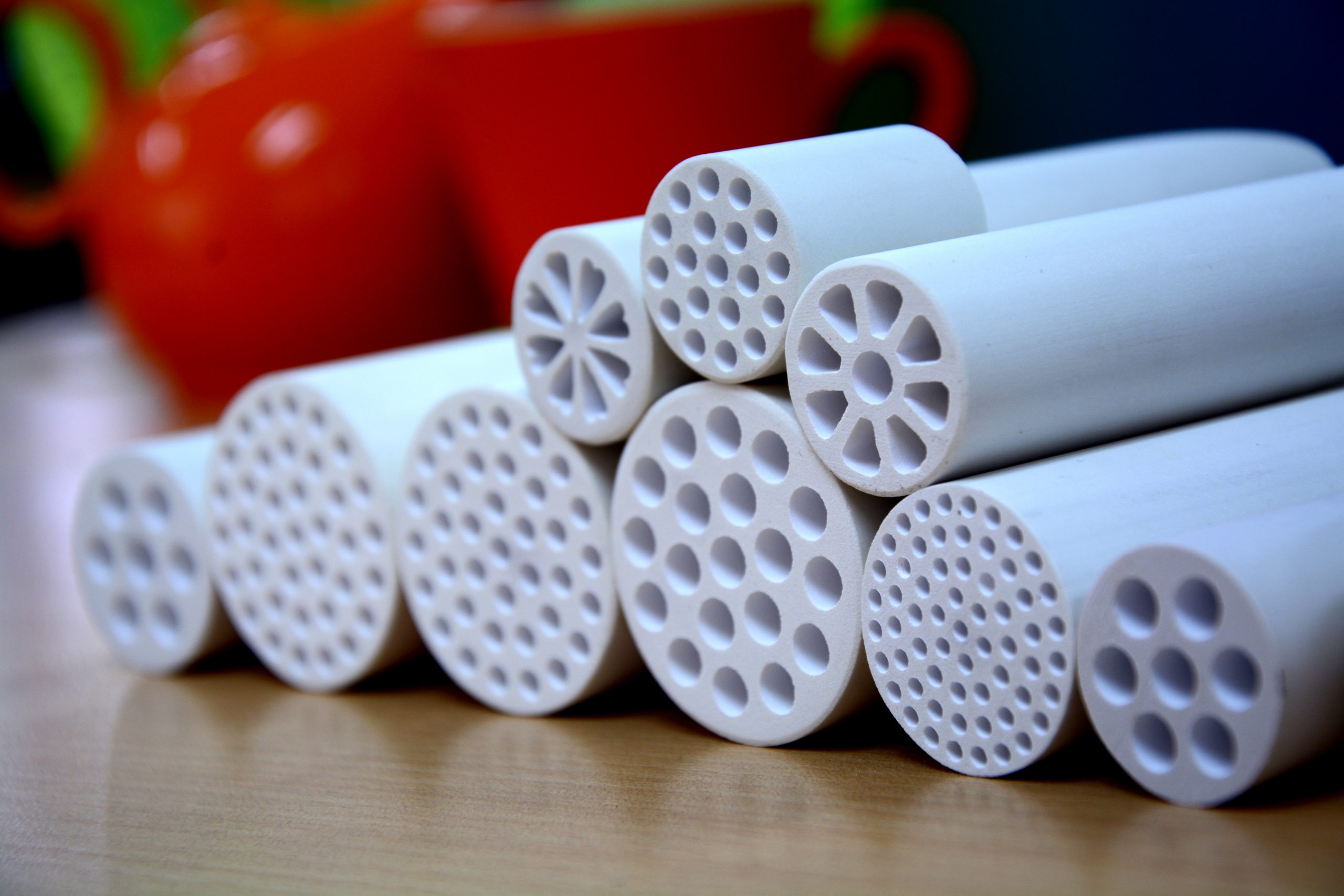

Ceramic Membrane

Porous ceramic membranes available with a pore size ranging from 0.01 to 10 μm cover microfiltration and ultrafiltration. The membranes with different geometry can be adapted according to the viscosity and the suspended solids content of the feed solution to achieve the requirement of specific clarification and separation.

Principal Advantages

Typical Applications

Flat Sheet Ultrafiltration (UF)

Principal Advantages

Typical Applications

Hollow Fiber Membrane

Principal Advantages

Typical Applications

Tubular Membrane

Tubular membranes are particularly suited to fluids with high viscosity and/or suspended solids and are easy to clean due to their wide flow channels. Pre-treatment requirements are minimal.

Flow channel can choose from 6mm to 12.5mm, according to the liquid specification. And filtration accuracy is available across the full spectrum of membrane processes from Microfiltration to Reverse Osmosis.