Suntar Technology

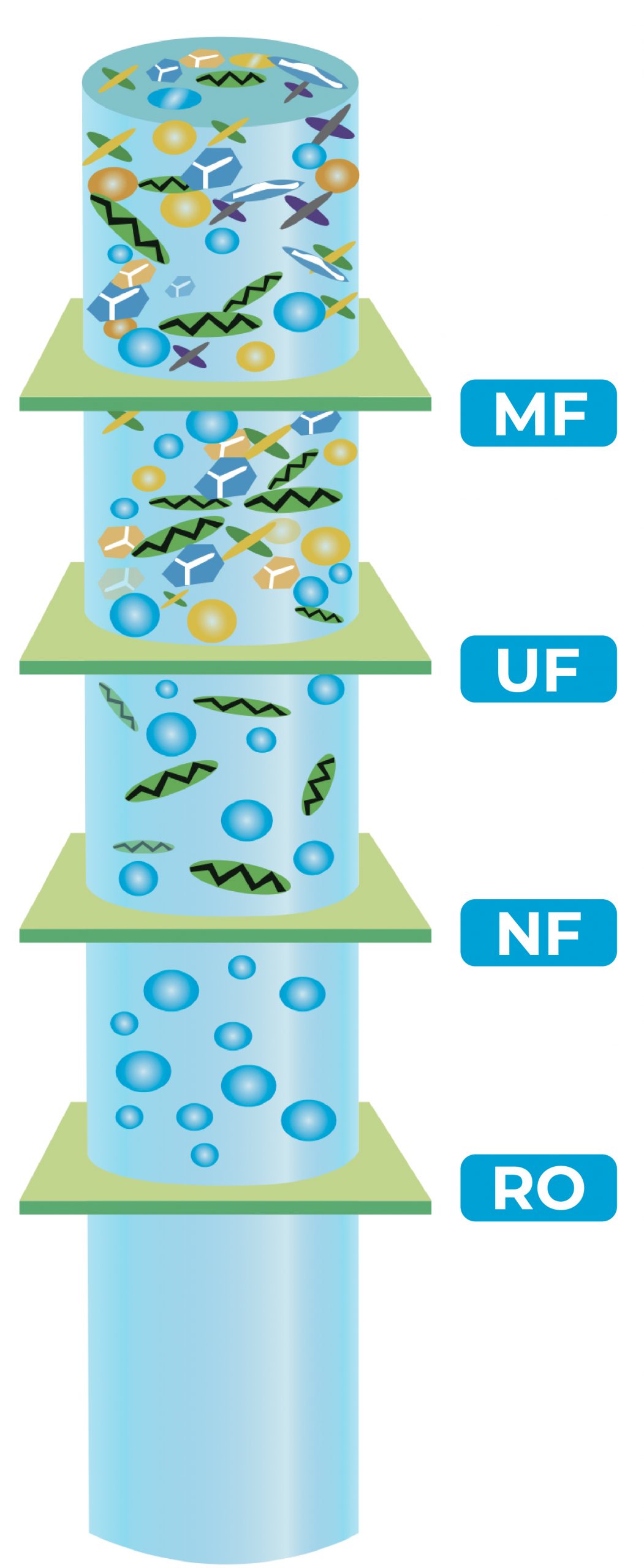

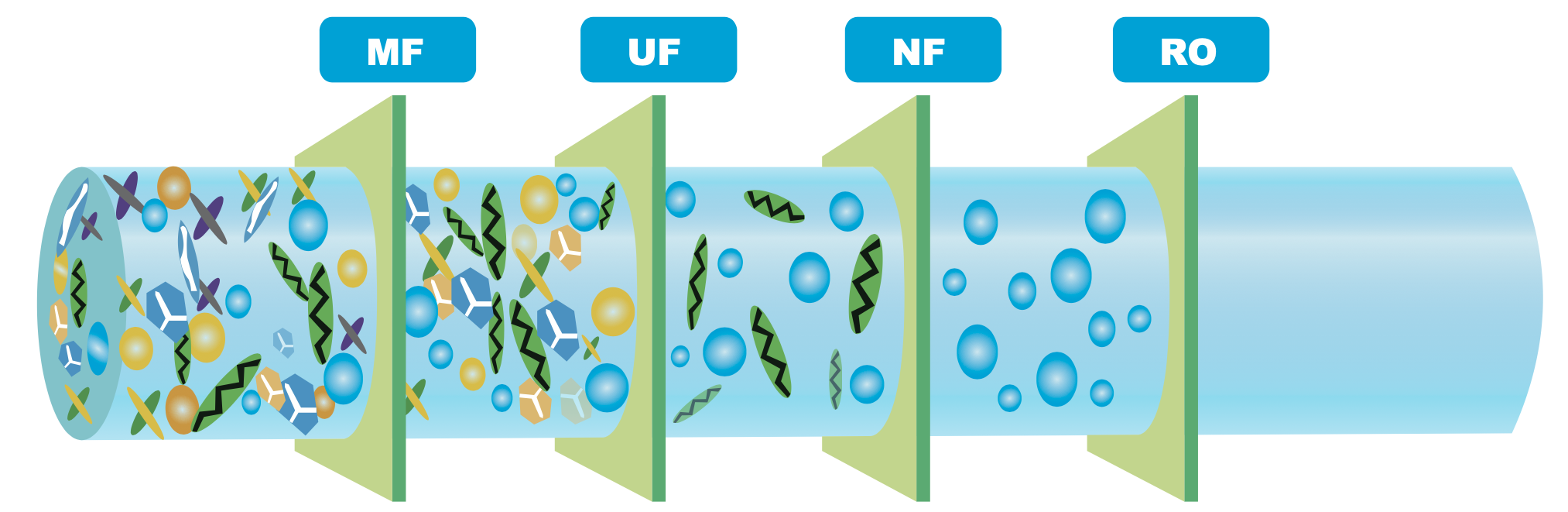

Different sizes of unwanted particles need different filtration methods to achieve the desired results.

Microfiltration

Microfiltration (MF) is loosely defined as a membrane separation process using membranes with a pore size of approximately 0.03 to 10 microns (1 micron = 0.0001millimeter), a molecular weight cut-off (MWCO) of greater than 1000,000 daltons, and relatively low feed water operating pressure of approximately 100 to 400 kPa (15 to60psi) Materials removed by MF include sand, silt, clays, Giardia lamblia, and cryptosporidium cysts, algae, and some bacterial species. MF is not an absolute barrier to viruses. However, when used in combination with disinfection, MF appears to control these microorganisms in water.

There is a growing emphasis on limiting the concentrations and number of chemicals that are applied during water treatment. By physically removing the pathogens, membrane filtration can significantly reduce chemical addition, such as chlorination. Another application for the technology is for the removal of natural synthetic organic matter to reduce fouling potential. In its normal operation, MF removes little or no organic matter; However, when pretreatment is applied, the increased removal of organic material can occur.

Ultrafiltration

Ultrafiltration (UF) has a pore size of approximately 0.002 to 0.1 microns, an MWCOof approximately 10,000 to 100,000 daltons, and an operating pressure of approximately 200 to 700 kPa (30 to 100 psi). UF will remove all microbiological species removed by MF (partial removal of bacteria), as well as some viruses (but not an absolute barrier to viruses) and humic materials. Disinfection is recommended as it can provide a second barrier to contamination.

The primary advantages of low-pressure UF membrane processes are compared with conventional clarification and disinfection (post-chlorination) processes are:

Membrane Filtration

Nanofiltration

Nanofiltration (NF) membranes have a nominal pore size of approximately 0.001microns and an MWCO of 1,000 to 100,000 daltons. Pushing water through these smaller membrane pores requires a higher operating pressure than either MF or UF.

Operating pressures are usually near 600 kPa (90psi) and can be as high as 1,000kPa (150psi). These systems can remove virtually all cysts, bacteria, viruses, and humic materials. They provide excellent protection from DBP formation if the disinfectant residual is added after the membrane filtration step.

Because NF membranes also remove alkalinity, the product water can be corrosive, and measures, such as blending raw water and product water or adding alkalinity, may be needed to reduce corrosivity. NF also removes hardness from water, which accounts for NF membranes sometimes being called “softening membranes.” Hardwater treated by NF will need pretreatment to avoid precipitation of hardness ions on the membrane. However, more energy is required for NF than MF or UF.

Reverse Osmosis

Reverse Osmosis (RO) can effectively remove nearly all inorganic contaminants from water. RO can also effectively remove radium, natural organic substances, pesticides, cysts, bacteria, and viruses. RO is particularly effective when used in series with multiple units. Disinfection is also recommended to ensure the safety of the water.

Advantages of RO

Limitation

Continuous Ion Exchange (IX) Technology

The Continuous IX Technology is a completely new innovation of separation technology, different from the traditional fixed bed, pulsed-bed, and simulated moving bed techniques.

Suntar continuous IX system adopts advanced design concepts and exquisite production technology, which can be applied in various areas with easy operation.

The system can be flexibly adjusted according to different separation requirements. So far Suntar has successfully supplied, installed & commissioned around 100 sets of continuous IX systems for different areas in an international customer base.

Principal Advantages

Typical Applications

Continuous Chromatography Separation Technology

Chromatography technology is an advanced separation method based on inter-molecular affinity differences. It is one of the effective strategies to separate materials with similar physical and chemical properties.

Suntar chromatography system is continuous chromatography separation technology. It is designed on the basis of traditional fixed-bed chromatography separation to achieve continuous production and exploit the advantage of chromatographic separation technology with full and rational utilization of the stationary phase.

Therefore, the whole system offers high quality, high efficiency, good stability, and low energy consumption.

Principal Advantages

Typical Applications

The separation between:

1. Sugar and salt like molasses

2. Sugar and alcohol like xylitol

3. Monosaccharide & Polysaccharide like Xylo-oligosaccharide

4. Different sugars like arabinose

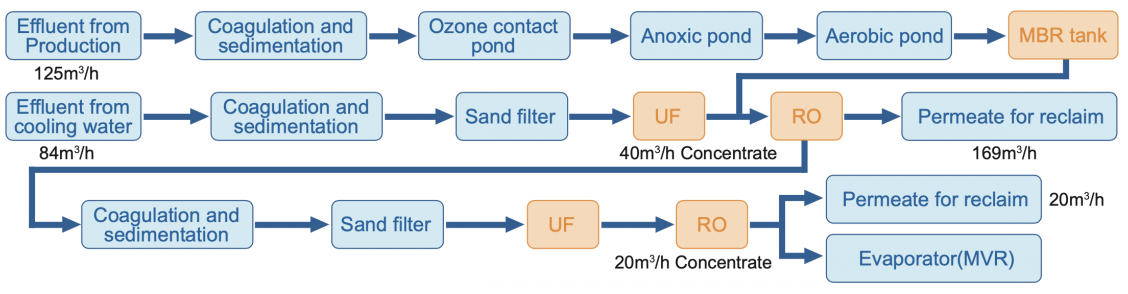

Membrane Bioreactor

MBR is a new waste water treatment process which integrates the advanced membrane separation technology with the conventional biological treatment process. It utilizes the micro porous structure of the membrane to retain the aerobic and anaerobic bacteria in the reactor, and increases the degradation efficiency of COD, BOD via increasing the biomass concentration, extending the solid retention time (SRT). Furthermore, MBR systems result in an excellent effluent quality and minimal footprint.

Basing on good experience of membrane application and biotreatment, Suntar provide the customized process design and most suitable configuration of MBR systems to meet the strict discharge standard of water pollutants and requirement for lower running cost.

Principal Advantages

Typical Applications