Case Studies

Wastewater Recycling Case Study

Case Study 1

Two stage membrane system to recycle wastewater:

- UF to remove suspended solids and microorganisms.

- RO to remove soluble salts and organic compounds.

- Recovery: 70% (5040m3/d)

- Salt removal rate: 95%

- Recycled water used in desalination system in place of municipal water.

Case Study 2

Wastewater discharged without further utilization.

Daily wastewater discharge: 15000m3/d

Two stage membrane system to recycle wastewater:

- UF to remove suspended solids and microorganisms.

- RO to remove soluble salts and organic compounds.

- Recovery: 70% (10500m3/d)

- Recycled water used to replenish the water supply tank in the production area

Food Tech Applications

Case Study 1

Conventional Method:

- Use of plate and frame filter press or centrifugation.

- Use of additional chemicals.

Poor clarity of desired peptide.

Lost of texture in the product.

Multiple step membrane system:

- MF to clarify solution and separate peptide from protein.

- UF to concentrate the peptide to desired concentration.

- Concentration factor: 20

- Higher purity

- No requirements of added chemicals

Case Study 2

Purification of water with 200µS/cm

Sanitary Equipment to be used

Multiple step membrane system:

- Sand Filter

- Active Carbon Filter

- Reverse Osmosis

- Water conductivity ≤10µS/cm

- Production Capacity 50m3/hour

Other Noteworthy Cases

- Lee Kum Kee Foods Co. Ltd (Seafood seasoning protein desalting)

- Golden Shell Pharmaceutical (Shellfish protein extraction)

- Rongcheng Hongde Marine Bio-technology Co. Ltd. (Fish protein desalting)

- Rongcheng Hongde Marine Bio-technology Co. Ltd. (Fish protein purification and concentration)

- Hubei Tallyho Food Processing Co. Ltd. (Canola protein clarification, desalting and concentration)

- PT Tereos FKS Indonesia

- ADM USA (Cedar Rapids)

- Tate & Lyle USA (London)

- Tate & Lyle Slovakia

- CJ CHEILJEDANG Corporation

- Meihua Group

- Fufeng Group

- THP Group (Vietnam)

- Wong Lo Kat

- JDB Group

- Damin Foods Co. Ltd.

- Coca-Cola

- Pepsi Cola

- Nestlé

- Master Kong

Metallurgy & Chemicals Case Study

Case Study 1

High heavy metal ion content in industrial wastewater

Water quality (mg/L)

- Cd: <0.2

- As: <0.2

- Pb: <2.0

- Zn: <4.0

- Cu: <0.5

UF with ceramic membrane to remove heavy metal ion in wastewater

Produced water recycled to production

Remove heavy metal ion significantly

90% recovery rate

Water quality (mg/L)

- Cd: <0.01

- As: <0.1

- Pb: <0.1

- Zn: <1.0

- Cu: <0.5

Case Study 2

Litihium sulfate in battery wastewater can be recovered and recycled

Battery wastewater contains 0.8% lithium sulfate

Two stage membrane system:

- UF to remove suspended solids and colloids.

- RO to concentrate lithium sulfate for recovery.

>3% lithium sulfate in RO concentrate

RO effluent conductivity <10us/cm

RO effluent can be recycled for production

Biotech Applications

Case Study 1

- High pigmented protein content

- High large molecular weight protein content

- Requires low temperature separation

- Low concentration of protein

Two step membrane system:

- Ceramic membrane to remove pigmented protein and large molecular weight protein

- Spiral wound membrane to concentrate collagen

- Able to maintain low operating temperature

- Concentration: Increased from 1 Brix to 15Brix

- Concentration factor: 15

Case Study 2

- High impurities content

- Requires high operating temperature

- Removal of bacteria

Developed MF system:

- Removal of impurities

- Recovering enzymes Removal of bacteria

- High quality enzymes

- >90% yield

PTA Wastewater Case Study

To treat purified terephthalic acid (PTA) wastewater for its client in the petrochemical industry, Suntar came up with a wastewater treatment solution comprising pre-treatment, anaerobic, aerobic, ultrafiltration and reverse osmosis membrane processes.

The end-product of the multistage wastewater treatment was high-quality water that met the recycling standards for circulating cooling water and preparation of pure water.

- Suntar conducted wastewater pretreatment to remove the materials and residue that might interfere with subsequent treatments.

- PTA wastewater had a high level of COD, Suntar decided to treat it via the anaerobic treatment process.

- The anaerobic treatment process is generally an appropriate solution for wastewater with high concentrations of organic material, such as COD. During the process, the anaerobic microorganisms helped to digest the biodegradable matter present in the wastewater, resulting in a lower COD.

- Suntar conducted primary and secondary aerobic wastewater treatment for the PTA wastewater – to help break down the contaminants further via microbial decomposition for easier removal.

- Suntar continued the wastewater treatment with its ultrafiltration and reverse osmosis membrane processes.

RESULTS

Through the multistage wastewater treatment approach, Suntar was able to produce water that met the recycling standards for circulating cooling water and the preparation of pure water out of PTA wastewater efficiently.

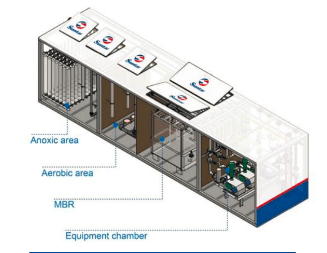

Yan’an MBR Municipal Sewage

MBR is a new wastewater treatment process, it integrates membrane separation technology and the conventional biological treatment process.

Suntar has developed a pioneering model, the Sheet MBR, a finer version of the Hollow Fiber and Flat Sheet, with improved performance, optimised energy consumption and a sustainable membrane cleaning process.

Suntar’s MBR technology has been applied across industries, and has effectively filtered harmful pollutants for municipals globally.

The structure encompasses four pairs of lines, in which each line weighs 1.25 tons. The system is made up of three units -the biochemical unit, the membrane unit, and the disinfection and production unit. In the biochemical unit, the wastewater is filtered through the anaerobic, anoxic, and aerobic treatment processes to breakdown biodegradable materials and denitrify. The filtered wastewater is then passed through the membrane filtration for the separation of biomolecules and particles. Sludge was refluxed in the aerobic and MBR zones. The wastewater is then disinfected and produced.

RESULTS

The water produced achieved a class IV standard, and Suntar exceeded all basic control indices.

Yan’an New Area Learning Academy

Suntar’s Membrane Box is an integrated sewage treatment system. It is a bioreactor that is capable of autonomous operation and may be located underground. The system is ideal for locations where connection to existing sewage systems is difficult and/or expensive, or where preserving the environmental aesthetic is vital. Suntar has installed hundreds of Membrane Boxes. One development where the Membrane Box was put to good use is Yan’an New Area Learning Academy in 2017.

Suntar’s intelligent bioreactor offers an integrated yet small-scale solution to such wastewater challenges.

RESULTS AND BENEFITS

The Membrane box at Yan’an New Area Learning Academy can treat up to 50 tons of wastewater a day. With Suntar’s membrane box, sewage can be easily managed while saving investment in a sewage pipe collection network. The membrane module is high quality, and the system has a low operational cost. Suntar Membrane Box is also easy to install and maintain. Furthermore, the project can be delivered in a short amount of time. Treated water from the system may be reused, allowing precious water to be conserved for other useful purposes, saving cost and benefiting the environment. The integrated system is designed to operate autonomously, with intelligent remote control built in.